Heat Treatment

Melting and Holding

Painting

Chi siamo

HTE Group è presente sui mercati internazionali da oltre 40 anni, progetta e realizza impianti di trattamento termico fusione ed affinazione dell’alluminio e linee di applicazione vernici antiaderenti e anticorrosive.

- Forni per trattamento termico

- Forni e macchine per attrezzeria

- Sistemi Fusori – Attesa – Degasaggio

- Verniciatura

ASSISTENZA E MAGAZZINO RICAMBI

Per garantire ai nostri Clienti un esemplare servizio di assistenza HTE e SN Furnaces dispongono di un fornito magazzino ricambi pronto per qualsiasi fermo impianto meccanico oppure elettrico. Grazie quindi alla disponibilità di semilavorati a magazzino, i ricambi speciali possono essere approvvigionati in tempi molto ridotti.

Per garantire ai nostri Clienti un esemplare servizio di assistenza HTE e SN Furnaces dispongono di un fornito magazzino ricambi pronto per qualsiasi fermo impianto meccanico oppure elettrico. Grazie quindi alla disponibilità di semilavorati a magazzino, i ricambi speciali possono essere approvvigionati in tempi molto ridotti.

In Italia la costruzione degli impianti avviene presso la nostra officina interna altamente specializzata ed attrezzata CMB Carpenterie Meccaniche Brambini SrL.

In Italia la costruzione degli impianti avviene presso la nostra officina interna altamente specializzata ed attrezzata CMB Carpenterie Meccaniche Brambini SrL.

Le grandi linee e forni di trattamento termico vengono costruiti in collaborazione con il partner tedesco OTTO JUNKER, avvalendosi di grandi officine attrezzate dislocate in Repubblica Ceca ed in Cina.

SN Furnaces

La ditta SN Furnaces fa parte del gruppo HTE-Novac ed è specializzata in

ricambistica, manutenzione ordinaria e straordinaria degli impianti.

Possiamo eseguire:

- Rilevamenti Fonometrici

- Analisi fumi gas di combustione

- Calibrazione di termocoppie

- Test Datapaq di uniformità

- Calibrazione velocità nastri e tappeti

- Termometri digitali e laser:

- per la rilevazione delle temperature

- per la ricezione dei dati delle temperature rilevate

- per lo sviluppo delle curve di temperatura con software in dotazione

- Equilibrature e bilanciature di organi in movimenti (ad esempio

ventilatori di ricircolo) - Prove anemometriche (ad esempio flusso d’aria di ricircolo all’interno

del forno, flussi di aria in condotti)

CMB Carpenteria

Entrata a far parte del gruppo nel 2016 la ditta CMB Carpenteria Meccanica Brambini è specializzata nella costruzione di impianti industriali e di opere in carpenteria leggera.

L’officina ha personale altamente qualificato e macchinari di ultima tecnologia Industry 4.0

La ditta CMB è in grado di lavorare diverse tipologie di metalli, quali acciaio al carbonio, acciaio inossidabile ed acciai refrattari.

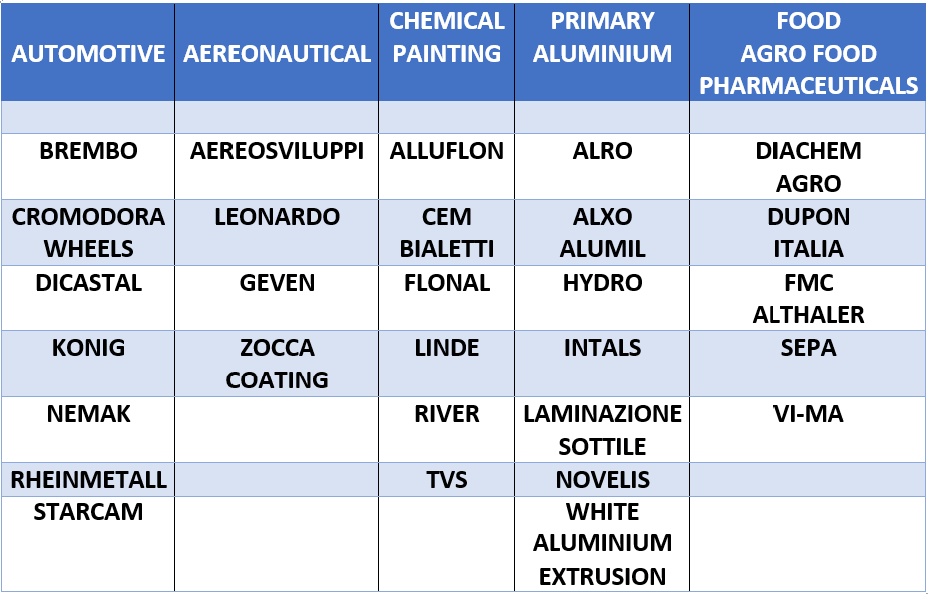

CUSTOMERS

More than 150

Customers worldwide

I nostri tecnici sono a vostra disposizione per ulteriori informazioni.

Forni per trattamento termico

Forni a cestoni

Forni basket free

Forni ad elevatore

Forni Coils & Foils

Forni traslabili

Forni flash annealing

Forni e macchine per attrezzeria

Stufe per distensione a 350°

Stufe per mantenimento stampi a 100°

Cabine di verniciatura stampi altamente evolute

Girafusti per venici

Miscelatori per vernici

Pistole di verniciatura

Fusione Attesa Degasaggio

Forni a bacino fissi

Forni a crogiolo fissi e rovesciabili

Forni rovesciabili per fusione ed attesa

Canaline di travaso alluminio mobili e fisse

Siviere trasporto alluminio

Riscaldi siviere

Sistemi per caricamento forni fusori

Sistemi per degasaggio alluminio fuso

Canaline di travaso e trasporto alluminio fuso

Piattaforme elevatrici per scorifica forni fusori

Verniciatura

Impianti per verniciatura industriale PTFE

Linee per applicazione vernice antiaderente spray

Linee per applicazione vernice antiaderente a rullo